Experience, knowledge, and commitment to success—let's talk about your mechanical assembly needs today. Call us at 925.292.1293 today!

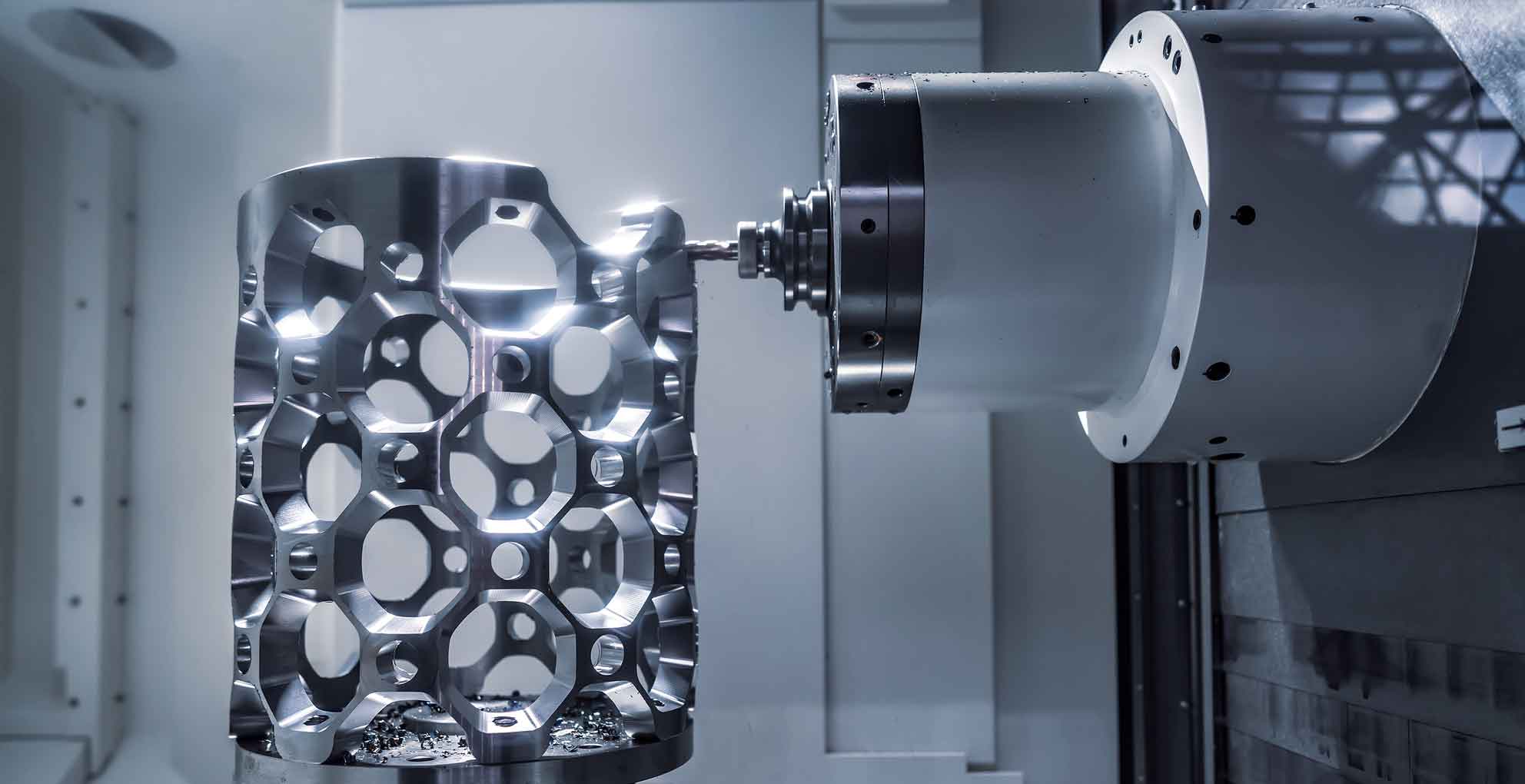

In-house precision machining with skilled workers who have more than 20 years of experience offers several advantages and benefits. Here are some key points:

- Expertise and knowledge: Skilled workers with extensive experience bring a wealth of expertise and knowledge to the precision machining process. Their years of hands-on experience enable them to understand the intricacies of machining techniques, tooling, materials, and quality control measures. This expertise helps ensure high-quality output and efficient production.

- Consistent quality: With experienced workers, in-house precision machining can maintain consistent quality standards throughout the manufacturing process. They possess a deep understanding of tolerances, surface finishes, dimensional accuracy, and other critical factors that contribute to producing precise machined components.

- Efficient problem-solving: Skilled workers with decades of experience have encountered various challenges in their careers.They possess problem-solving skills honed over time.This enables them to identify issues quickly,troubleshoot effectively,and find optimal solutions when faced with complex machining problems or unexpected obstacles.This efficiency minimizes downtime,reduces costs,and ensures smooth operations.

- Adaptability and versatility: Experienced machinists are often versatile in working with different types of materials (metals, plastics, composites), as well as various CNC machines or manual equipment.They can adapt their skills to handle a wide range of projects or customer requirements.This flexibility allows for efficient utilization of resources within the facility.

- Continuous improvement: Skilled workers who have been in the industry for many years often have a mindset focused on continuous improvement.They stay updated on advancements in machining technologies,new tools,and techniques that can enhance productivity,optimize processes,and improve overall efficiency.Incorporating these improvements leads to better results over time.

- Cost savings through reduced errors: In-house precision machining by experienced professionals reduces the likelihood of errors during production.Their expertise helps minimize mistakes related to programming,machine setup,tolerances,machining strategies,and tool selection.Reducing errors leads to cost savings by minimizing scrap,rework,or rejected parts.

- Shorter lead times: Skilled workers with extensive experience can work efficiently and effectively, reducing lead times for precision machining projects. They understand the importance of meeting deadlines and can optimize their workflow to deliver results within tight schedules.This shorter turnaround time benefits customers who require quick production or urgent orders.

- Knowledge transfer and mentorship: Having skilled workers with more than 20 years of experience provides an opportunity for knowledge transfer and mentorship within the organization. Younger or less experienced employees can learn from their seasoned colleagues, acquiring valuable skills, know-how, and best practices. This ensures a strong talent pipeline and promotes continuous improvement in the long run.

In summary, in-house precision machining with skilled workers who have more than 20 years of experience offers advantages such as expertise, consistent quality, efficient problem-solving, adaptability, cost savings through reduced errors, shorter lead times, knowledge transfer, and mentorship. These benefits contribute to high-quality output, optimal utilization of resources, and improved efficiency in precision machining operations.