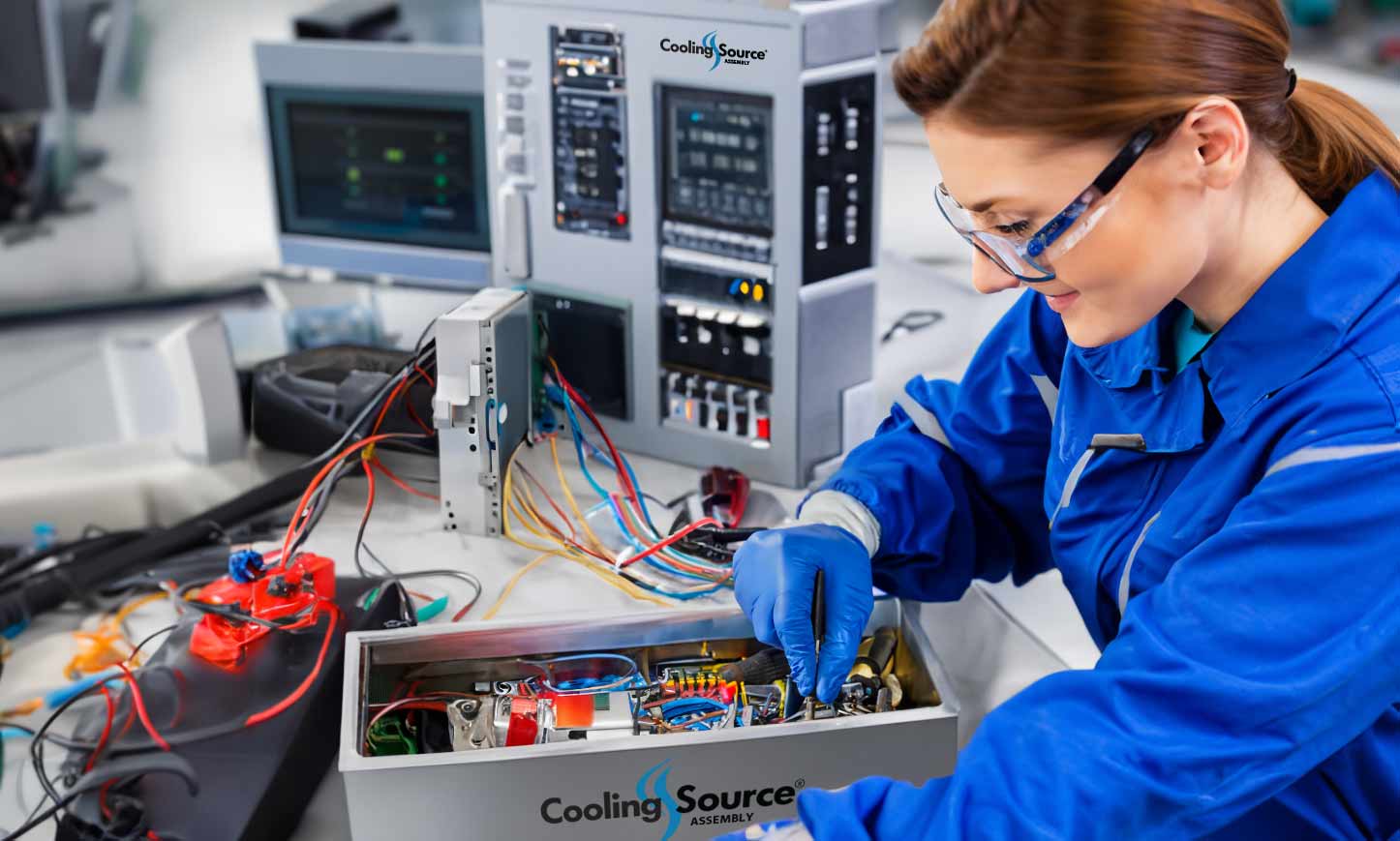

Electromechanical Box build refers to the process of integrating various electronic components, mechanical parts, and subsystems into a complete enclosure or box. Here are some ways in which Electromechanical Box build can save you time and improve efficiency:

1. Streamlined procurement: Instead of sourcing individual components from multiple suppliers, Electromechanical Box build allows for centralized procurement. This simplifies the supply chain management process, reduces lead times, and minimizes the effort required to coordinate with different vendors.

2. Reduced assembly time: With Electromechanical Box build, many components are pre-integrated or pre-assembled before they are installed into the enclosure. This eliminates the need for individual component assembly during final integration, saving significant time in the overall manufacturing process.

3. Improved compatibility: During Electromechanical Box build, compatibility between different components is carefully considered and ensured beforehand. This helps avoid issues related to fitment, mounting, sizing, and electrical connections that may arise when integrating disparate components individually. Improved compatibility leads to smoother assembly processes and reduces troubleshooting efforts.

4. Enhanced quality control: By assembling all necessary components within a controlled environment, Electromechanical Box builds allow for comprehensive quality control measures. These measures can include functional testing, integration testing, and inspection procedures at various stages of assembly. Enhanced quality control ensures that potential issues are identified early on, reducing rework or post-assembly problems.

5. Standardized processes: Electromechanical Box builds often follow standardized procedures and workflows. This standardization improves efficiency by reducing variability in assembly methods, enabling faster training of personnel, and ensuring consistent results across multiple units. Standardized processes also facilitate scalability as production volumes increase.

6.Optimized space utilization: Integrating various electronic and mechanical components within a single enclosure maximizes space utilization. This eliminates wasted space due to separate component mounting, reduces cable clutter, and enhances overall system compactness. Optimized space utilization not only saves physical footprint but also facilitates easier installation, maintenance, and servicing.

7. Simplified logistics: Electromechanical Box builds simplify logistics by consolidating multiple components into a single package. This reduces the number of shipments, handling procedures, and associated paperwork. It also simplifies inventory management and reduces the risk of component loss or damage during transportation.

8. Faster time-to-market: By streamlining procurement, reducing assembly time, improving compatibility, enabling quality control, and optimizing space utilization, Electromechanical Box builds can significantly shorten the overall product development cycle. This allows for faster time-to-market and enables companies to respond quickly to market demands, gaining a competitive edge.

In summary, Electromechanical Box build saves time and improves efficiency through streamlined procurement, reduced assembly time, improved compatibility, enhanced quality control, standardized processes, optimized space utilization, simplified logistics, and faster time-to-market. These benefits contribute to increased productivity, reduced costs, and improved customer satisfaction in various industries where complex electronic systems are involved.